What do you do with that busted Compression Tester? Alter it so you can pump air into a cylinder and see where it goes.

I imagine one could probably create a pseudo leak-down tester by incorporating a pressure gauge, but I haven’t gotten there yet.

Now, to do this, you need to excuse the fact that I wasn’t exactly thinking at the time.

I cut off the dead gauge (not shown), and cut the hose barb ferrule off with a hacksaw so I can get at and remove the check-valve inside.

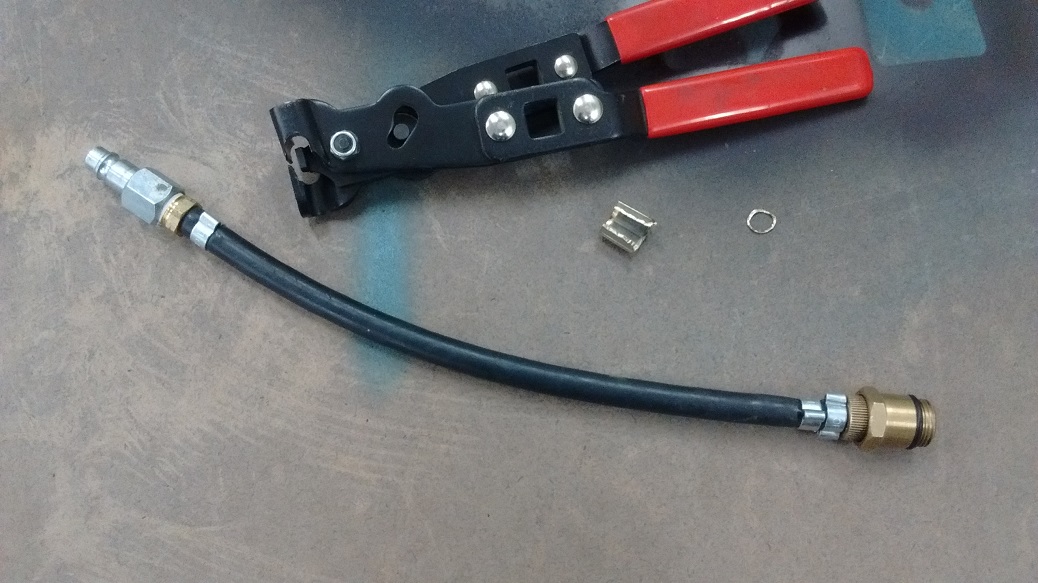

Now would have been a good time to drill the end out and disembowel the threaded end, but I was excited, and quickly clamped it back together, using two crimp hose connectors to make sure it didn’t come loose in the bottom of a spark plug well. I use CV boot pliers.

I happened to have a wee NPT barb, so I put an air fitting on what was formerly the cut end.

So now you have something like this:

This was when I realized I forgot to gut the thing. Short work with a 1/4″ drill bit (probably didn’t need to even cut the hose off….), drilling until it feels like you broke through something:

Haven’t used it yet, but I’m looking forward to.

Also handy for holding valves up while changing valve springs while the heads are still on.