[The Engine] [Cylinder Heads] [Engine Blocks] [Fuel System] [Ignition System] [Cooling System]

Click to Print – QUESTION SHEET |

Things we are going to look at:

|

PURPOSE |

|

1. To bring the engine up to operating temperature quickly

2. To maintain an optimum operating temperature

3. To heat the passenger compartment

|

ANALOGY |

|

In the metal shop, we often use the Blacksmith Forge to heat and shape metal. I can cool the metal off in a bucket of water, which absorbs the heat.

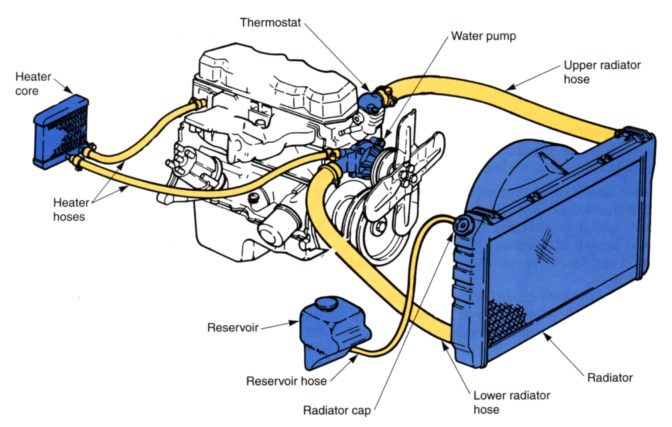

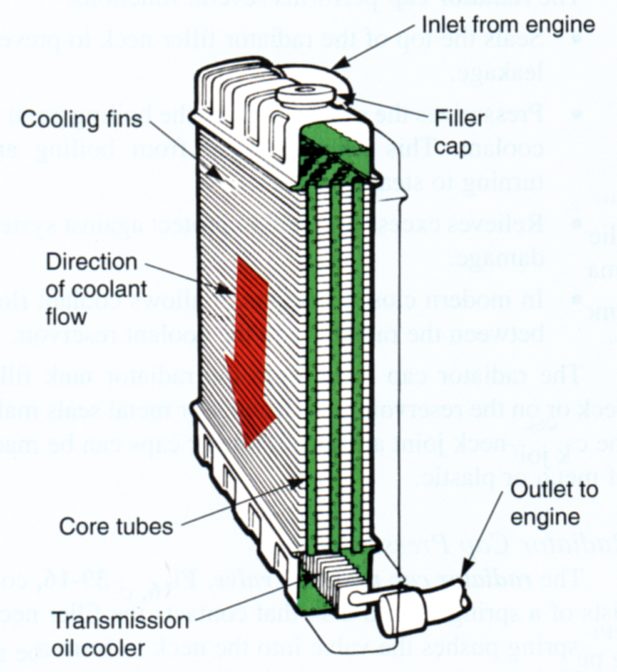

If I do this enough, eventually the bucket of water will become so hot, that it no longer cools the metal adequately. If I hired some lackey to blow on the water to cool the water down, I could continue to work with the metal. The cooling system is very much like that. We will (usually) use water to absorb the heat of combustion from the engine block and heads, then pump that water to a radiator (rad) where a fan will blow the heat away. If the heat doesn’t get into the water, if the water does get pumped to the rad, if the water doesn’t flow through the radiator, if the heat doesn’t conduct to the cooling fins in the rad, if air doesn’t blow over the rad, if the hot air cannot escape, you will have an overheating problem. If the water has no temperature-controlled restriction, and the water goes quickly and constantly to the radiator, you will have an underheating problem.

NOTE: Both Overheating AND Underheating will kill your engine!

|

TYPES |

|

There are two types of cooling systems. Air Cooled: A fan blows air over cooling fins on the cylinder (eg: Old Porsche 911’s, old VW Beetles, the Chevrolet Corvair, the first Honda cars, the Berkeley sportscar, etc.). You really don’t see these any more.

Water Cooled: A pump circulates coolant through water jacketing around the cylinders absorbing heat which is dissipated by a radiator with a fan (eg: Everybody else)

|

|

|

COOLING SYSTEM PARTS |

|

|

RADIATOR CAPThe radiator cap provides a place to fill the cooling system and acts as a “Pressure Relief” valve – it actually makes sure the system operates pressurized. Engines work best if they are operating at about the boiling point of water. The higher the temperature (within reason) the better it is for the engine. This is all good until the water actually boils. While water does an excellent job of absorbing heat from the engine, boiled water (steam) cannot remove heat and the engine will be ruined. To prevent this, we need to increase the boiling temperature of water. One way to do this, is to pressurize it (although we need to release too much pressure, so something doesn’t pop).

The Propane in your BBQ tank at home boils at -40°C. In our world, propane is usually a gas. Yet when you shake the tank, you can feel that it is a liquid inside. The tank is a pressurized cylinder, and enough propane is put in to pressurize the cylinder to about 300psi. This pressure actually raises the boiling point of propane so that it will stay a liquid above -40°C). Once you open the tank you are releasing the pressure, and the propane will INSTANTLY boil – because it should have boiled 60-70°C ago! The boiled propane comes out as “steam” (the white cloud of gas you see). Water is the same! If we pressurize it 15psi (typical), water will now boil at 125°C instead of 100°C! Many engines today ACTUALLY OPERATE above 100°C!!

The rad cap raises the boiling point by pressurizing the cooling system. Most caps provide around 15psi pressure. Metric caps are rated in Bar: 1 Bar = 1 Atmosphere 1 Bar = 100kPa (KiloPascals) 1 Bar = 14.7psi (atmospheric pressure, in Pounds Per Square Inch). The rad cap also bleeds off excess pressure as a protection to the system. In the bad old days we just puked the coolant all over the ground. Today, since engine coolant is fatally toxic, modern systems puke it into a coolant recovery tank, where it is drawn back into the system when the coolant cools and contracts. Radiator caps should be checked with a pressure tester to see what pressure they release at. If they do not meet their rated pressure, or if either of the seals are worn out, it should be replaced.

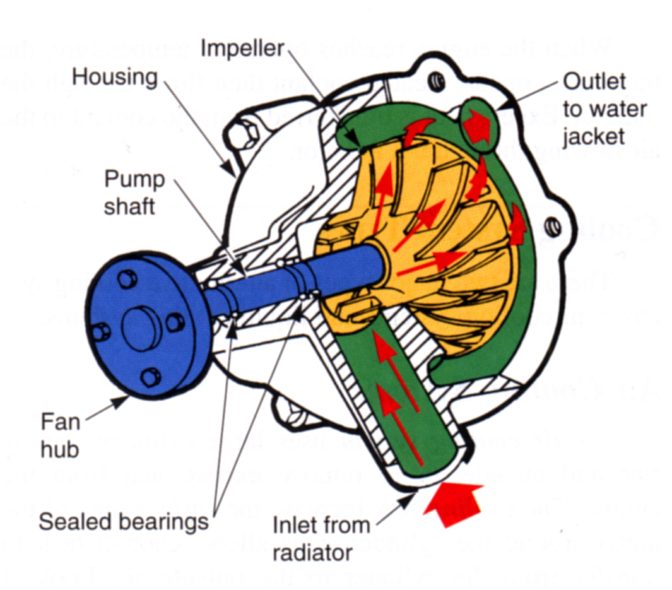

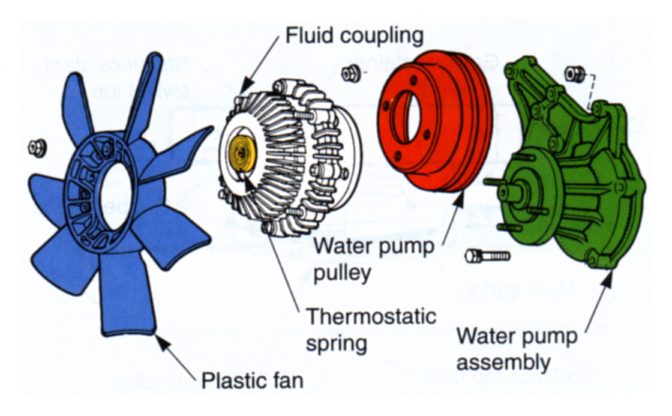

WATER PUMPThe water pump circulates the coolant through the engine (to heat up) and radiator (to cool down).

There is a seal on the impellor end of the pump shaft to keep the coolant inside. If the shaft seal of the pump were to leak, coolant would come out, get into the pulleys and fan, and spray everywhere making a colossal mess. But seals don’t last forever. To avoid a colossal mess, water pumps have a bleed hole between the inner seal and the pump shaft bearings. If the inner pump seal starts to leak, the coolant is re-directed through this hole and away from the spinning pulleys and fan – an easy way to see if that pump is on its way out. Water pump bearings can be checked by grabbing the fan/pulley and rocking it back and forth. Any play indicates worn bearings, and worn bearings will eventually cause the seal to leak (too much movement). Occasionally, the impellor falls off old water pumps. You may hear this as a weird rattling sound as the shaft smacks the now loose impeller floating inside the pump housing. A detached impeller would reduce cooling efficiency. I’ve only ever seen the impellor rust off from people who ran straight water, not an antifreeze/water mix. Water pumps used to be rebuildable, but it is no longer cost-effective to do this.

THERMOSTATWay back in Fuel Systems we mentioned how we added EXTRA fuel into the engine when it was cold, and how important it is to get the engine up to operating temperature quickly. With simply a water pump and a radiator, we run the risk of overcooling our engine (this equals extra fuel which is bad for fuel economy, bad for the environment, bad for our oil, and bad for our engine), and if not overcooling, certainly very slow to warm up. What we need to do is hold all the coolant in the engine until the engine is up to proper operating temperature, and then send it to the radiator to maintain that proper operating temperature. The part we use is called the Thermostat.

The thermostat is a simple valve that has a pellet of wax inside that expands when heated. When it expands, it pushes open a round disc that allows hot coolant to flow from the engine into the radiator hose that goes to the radiator. OLD SCHOOL ENGINES usually had the thermostat at the TOP of the engine, in the LAST place the coolant went before the radiator. This would probably OVERCOOL the engine BLOCK, but keep the cylinder HEADS at a CONSISTENT temperature. MODERN ENGINES now place the thermostat on the LOWER radiator hose, where cold coolant enters the block. This would probably maintain a CONSISTENT BLOCK temperature (good for oiling, bearing life, ring life, better combustion, less pollution), and the cylinder HEADS would tend to run HOTTER especially underload (better for combustion, less pollution).

CORE PLUGS, NOT FROST PLUGSThe first rule of Frost Plugs is to not call them Frost Plugs

The Core Plugs are there to hold the “core” when the engine block is cast from molten metal. When an engine block is made, molten metal is poured into a hollow from called a “mold” (this is “metal casting”). Since there need to be passages in the engine, a “core” (made in the shape of the passages) is held in the mold for the metal to pour around.

Fascinating Link: How an Engine Block is Made

When the freshly cast engine block has cooled, the core (kind of a glued-together-sand) is broken out, and the holes where core was supported in mid-air need to be plugged. *cough* “Core Plugs.”

Theoretically: “frost plugs” will pop out if you were running straight water, and the water freezes and expands (Science: water expands when it freezes!). Reality: Water doesn’t care – and it will crack the weakest spot.

Core plugs are usually removed with a large punch and a hammer. One side of the core plug is punched into the water jacket. The opposite end usually swings out, and is grabbed by a pair of water pump pliers and removed from the block. New core plugs have their sealing surface coated with Aviation Form-a-gasket, and are inserted using a large deep socket and a hammer. Core plugs are inserted until the flanged edge is just flush with the block surface. It is a false economy to reuse old core plugs. On most cam-in-block V-engines, a core plug caps the end of the rear camshaft bearing (the cam journals are bored all the way through the block; the end has to be capped). It is very important that this plug be installed – otherwise your engine will lose ALL its oil pressure out the back of the block and your engine will weld itself together. Block heaters usually replace one (or more) core plugs. They look like a tea kettle heating element, and allow you to plug your car in during a cold spell – it heats up the coolant just like a tea kettle. Yummy.

|

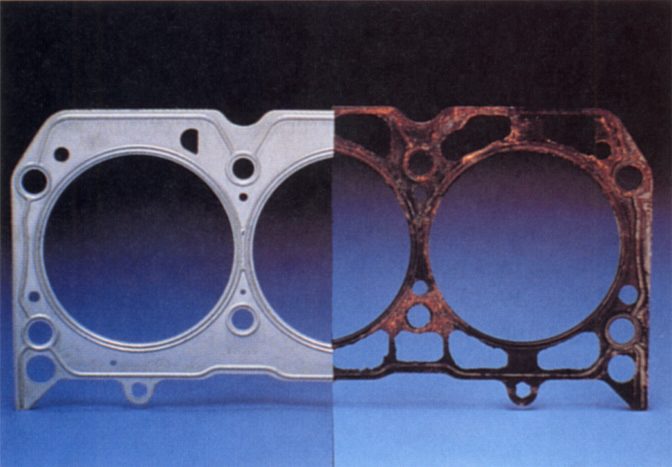

HEAD GASKETGaskets seal the major parts of the engine. They prevent oil, anti-freeze and cylinder pressure from mixing together. Head gaskets are a critical gasket, as they also have to seal combustion forces!

If the head gasket lets coolant into the combustion chamber, the chamber will get a thorough cleaning (the cylinder will look completely clean of carbon on disassembly), and the exhaust will be a very smokey white. If the head gasket allows combustion gasses into the cooling system, the engine will overheat very quickly on the highway, but not while idling or puttering at low speed. No cooling system in the world can cool combustion gasses in the cooling system! (I’ve tried) One quick way to see if your head gasket is blown, is to open the radiator cap while it’s running. If you see millions of tiny bubbles, it is likely that the head gasket is letting combustion gasses into the cooling system.

My son and I had to rebuild the engine in his car because a coolant leak we didn’t catch caused the headgasket to blow, and the overheating took out the piston rings. Oh, and we discovered that the bearings were shot too: COOLING FANA cooling fan draws air through the fins of the radiator – it keeps air moving so the heat can be drawn away. Traditionally, the cooling fan was mechanical – it was physically attached to the water pump and drive by a belt on a pulley. Even front-wheel-drive Austin Minis had an engine-mounted fan – BMC just put the radiator on the inner fender to make it work!

Most front wheel drive cars use a transverse-mounted engine (the engine is crossways in the engine bay, not inline with the chassis), so it is just easier to keep the rad up front in the air stream, and run an electric fan instead of an engine-mounted mechanical one.

It is turned on by a system of sensors and relays when the engine reaches about 200°F and stays on until the coolant is cooled to about 195°F. Some vehicles with electric fans may allow the fan to turn on even if the engine is not running. You should always keep your fingers away from the cooling fan! The fan “switch” is often located in the “cold” tank of the radiator – it will turn on if the radiator is not adequately cooling the engine by itself. The sensors usually fail in the “OFF” position. In a pinch, you can often bare the wires and twist them together to make the fan run constantly – it’s better than overheating your engine! Switching from a mechanical fan to an electric fan can free up a considerable amount of power!

FAN CLUTCHA Fan Clutch is a way to let a mechanically-driven fan “coast” when it is not needed, thus freeing up power and fuel economy. It senses the air temperature coming through the radiator and either slips (coasts) when cold, or binds up when hot to pull the air through the radiator. It is entirely mechanical, no electricity at all.

You can tell when a car has a fan clutch when you start it up in the morning and you can hear a loud rushing windy sound from under the hood that lasts maybe a minute then goes away. That is the clutch loosening up. If the sound never goes away, the clutch is probably stuck “on.” A fan clutch usually fails in the “on” position. Why do you think that is?

HEATER COREUp here in Canada it gets cold in winter. If only there was some source of heat within the vehicle to keep us warm. Hmmmmmm…….. While we are using a big radiator to get rid of heat from the engine, we can also use a wee mini radiator and a wee mini fan INSIDE the car to heat US. That sounds awesome! The most common issue with heater cores is leaks. Leaks tend to show up as wetness on the floor and carpet of the passenger footwell, or as steam coming up through the defrost vents.

Replacing a heater core can be either super easy, or it can be one of the most wretched experiences you can have with a car. Depends on the vehicle. Usually it’s a “not fun” job to do.

COOLANT

Water only? Okay… Way back in the bad old days, we used to use water. Water does a GREAT job of cooling things down (fire departments use it!). Bad news: Water rusts the steel, and starts to dissolve the aluminum (dissimilar metals = battery = galvanic corrosion) Water boils too soon Water freezes We used to use alcohol in winter, which doesn’t freeze. Bad news: Alcohol evaporates, and ZERO coolant doesn’t cool very well. When my parents were first married, my pops would wake up at night every hour to start and run the truck up to temperature so that it wouldn’t freeze and then go back to bed.. If only there was a different way….. There IS a different way:

If we add Ethylene Glycol to water, we can both prevent freezing AND prevent boiling! A 50/50 mixture of Ethylene Glycol and water is a perfect mix for good heat absorption and no-freezing. Coolant also lubricates the water pump and prevents corrosion. Straight antifreeze (no water added) would not work very well because it doesn’t absorb heat like water does. 75% water and 25% antifreeze absorbs heat really well and also reduces corrosion, but does not provide enough protection from freezing. Coolant should be changed every two years, as it becomes acidic over time. There is “long life” coolant which lasts about 5 years, and some that allegedly last longer… Some long life coolants mixed with regular life coolant turns into jello, which doesn’t cool at all (I’m looking at you, Dexcool!).

DANGER:GM’s Dexcool Coolant + Generic Coolant = PUDDING!

I’m not even sure how you get that out of the system.

Ethylene Glycol is sweet tasting, and very poisonous. You can check a Material Safety Data Sheet and figure out how much will kill you (look in Section 11: Toxicology – it will say how much it took to kill a 1kg rat – do the math 🙂 tip: there are 1000mg in a g, and 1000g in a Kg). For this reason: always clean up any spilled coolant! Modern coolant has a “bittering agent” in it to make it less tasty, and it IS less tasty (I’ve tasted both).

ARTICLE: Ethylene glycol poisoning

Used coolant can be recycled – take it to a collection facility (Canadian Tire), DO NOT dump it down the drain or in a ditch.

TESTING THE COOLING SYSTEMPeriodic inspection and testing can ensure years of trouble-free motoring. Leaks are the most common fault of the cooling system. They can be checked for visually, by pressure-testing the cooling system to it’s rated pressure, or adding a dye to the coolant and using a black light to help see the leaks externally. Coolant strength can be tested with an Antifreeze Tester. It is much like a Battery Hydrometer, and determines strength based on the density (specific gravity) of the coolant.

PRESSURE TESTINGThis is a good way to find out if you have any leaks, OR, if you know you have leaks, it helps you find them. ONLY pressurize the system to the RATING ON THE CAP (usually only about 13psi or so). DON’T be like the kids in my class years ago who pressurized the Grand Marquis until they actually popped the water pump – $100 bucks down the drain.

RADIATOR CAP TESTINGI’ve never seen a “good” rad cap in all the beaters that come through these doors. Caps are cheap, but even a “NEW” cap doesn’t mean it’s any good. I’ve seen bad “new” caps. NEW just means it Never Ever Worked.

SERVICING THE RADIATORRadiator should be replaced when the fins are crumbling due to corrosion, or when it cannot be cleaned inside due to corrosion or sediment built-up. Expect a radiator to last approximately 10 years.

SERVICING THE COOLANT HOSESHoses should be replaced every four years.

SERVICING THE THERMOSTATThermostats are usually replaced only when they fail. In the bad old days, we used to install a 160°F thermostat in summer, and install a 195°F thermostat in winter. Today, you run what the manufacturer recommends, and replace it only when it fails.

SERVICING THE COOLANTEngine coolant should be replaced every two years. “Long Life” coolant should be replaced every five years. I recommend buying CONCENTRATED coolant, and then mixing it 50/50 with DISTILLED water. If you see mineral deposits on your taps at home, you need DISTILLED water – those mineral deposits start to INSULATE your engine from the coolant! You can buy PREMIXED, but it’s twice the price per volume, though it IS convenient.

SERVICING THE BELTSFan Belts should be replaced every four years. It’s a good idea to keep one in the trunk with a couple cheap wrenches. Any belt that shows cracks, glazing, missing parts, fraying, etc, should be replaced.

WHEN THINGS GO WRONG“REBUILD IN A CAN”I’m not a big fan of these, but sometimes…… Sometimes an engine gets pretty gummed up from lack of maintenance. In these cases, you need to perform a “Cooling System Flush.” Follow the directions on the can. For example: Add one can to coolant Run engine for 10 minutes Drain water immediately, and flush with fresh water until water runs clear. Sometimes (and by sometimes, I mean usually), this loosens up all the goo that holds it together. In these cases, you add a can of goo to seal it all up again. Assuming that even makes sense.

Well this was unexpected (interesting video about cooling, but won’t be on the quiz):

|