[ Heinous Honda ] [ Suspension ] [ Drivetrain ] [ Miscellaneaous ] [ Racing ]

Wheels and Tires

Since I intended to turn this car into a “Corner Burner,” the first order of business was tires. I bought a pair of used 15×7″ aluminum rims with 5″ backspacing and bald mismatched 195/50R15 tires. I ran these bald tires for about a year before I broke down and bought new Yokohama Avid T4 tires. Being rather stingy, I bought the cheapest tires the tire guy offered. No, they don’t stick like glue, (they have a tread wear rating of 420) but they actually last a long time. The nice thing about them is they have decent grooves in them for rain. I run a separate set of 13″ rims with winter tires for the snow season.

The Yokohamas lasted approximately 35,000km before having the inside edges destroyed because of a loose tie rod end and 1″ of toe out. …and a full season of autocross racing at the very abrasive Boundary Bay Airport. The Yokohamas were replaced by Kumho Ecsta Supra 712 tires. These are rated at 340 treadwear, and are classified as an “Ultra Performance Tire.” The 712 is a directional tire, with a huge honking groove down the centre for rain. It is NOT an all-season tire, and it IS cheaper than the Yokohamas were. I am very happy with these tires.

When the BCMA Novice Series ended, I learned that BF Goodrich had pulled out of motorsports, and despite being sponsors of the series, could not provide the novice winners with race tires. Being desperate to go fast, I broke down and bought some anyway.

I picked up a set of used P185/60R13 Toyo Proxes RA1 tires from a local fellow who road races, but was going to 14″ tires for the following year. These tires whet my appetite enough that I went out and bought some new ones.

The Toyo Proxes RA1 is a DOT legal competition tire. It has a tread wear rating of 40, and is a “full tread depth” tire. It is often favoured as a rain tire, but it is not as fast as a Kumho V700, BFG R1, or Hoosier. I like them because they are cheap. And I can get them locally. They don’t stick super well until you wear through the initial tread which, fortunately or unfortunately, does not take long.

If I had more power, I would have gone for a P205/60R13, as there is more tread on the road. A large number of SCCA National Champions squeeze P215/50R13’s onto the factory 5″ wide rim. It seems ludicrous to me, but they are fast. Unfortunately as of this writing, the only 215’s available are Yokohama A032R’s which are not soft enough to make the switch worthwhile.

Sway Bars

DIY below:

My first attempt at sway bars was to adapt a pair of sway bars from a Turbo Chevy Sprint (merely because I happened to already have one, that’s why – see Firefly), and fabricated brackets to hold them. My theory was that if I stiffened the front and rear with the same type of bar, it should be maintain the stock balance. It would have worked, too, if the front and rear suspension were of the same design.

On the front I welded plates to the bottom of the torsion bar tubes, threaded to mount the sway bar center mounts. These mounts were exactly below the factory sway bar center section to minimize any binding of the suspension. The end links were merely U-bolts to the control arms with heater hose around the bar as an insulator. I believe the bar’s diameter was 7/8″ or so.

On the rear, I used muffler clamps around the axle tube, and welded brackets from the hatch floor’s sub frame down to meet the sway bar, which extended rearwards of the axle and attached to the bracket with U-bolts and heater hose.

These bars on the car resulted in vicious oversteer. On a wickedly fun twisty road from Lumby to the Needles Ferry (You gotta know the Okanagan/Kootenays), you had to keep your foot buried to keep the front end ahead of the back.

The next modification was to replace the front Sprint bar with a second Honda Civic bar (exactly the same as stock, but now mounted underneath the car). This resulted in a very neutral balance, with the ability to oversteer when persuaded. The body roll was dramatically reduced, however the front didn’t seem to turn-in as nicely. I drove it on the street this way for about a year, and raced it once (which ate my transmission).

The Civic bar is much smaller in diameter than the Turbo Sprint bar, but since it’s arms extended closer to the hub end of the suspension, the effective force applied to the control arm is larger.

I picked up a used Lightspeed Racing rear sway bar and installed it, driving it for about three months. This bar, with the second factory bar, removed the car’s oversteering tendancy, and in competition made it difficult to corner fast, as the front end would push (understeer). A good solution would be to remove my second front bar. Most racers don’t even bother with a front bar at all. The lightspeed sway bar is approximately 26mm in diameter (or was it 30?).

When I returned my car to be eligible for H/Stock competition, I ran just the Lightspeed bar on the back – A nice balance! I was really impressed – it did not seem to oversteer as viciously as I had anticipated. Nice!

If you’re on the cheap and don’t mind using factory parts, use a front sway bar from a Civic Wagon (Wagovan?) or 86-89 Acura Integra. The Integra RS bar appears to be larger than the much more common Integra LS, yet about the same size as the Wagon. The solid rear axle comes with an integral sway bar inside the axle housing. Apparently the rear bar from a Civic is 15mm, most Integras are 17mm, and the Integra SE is 19mm. When messing with suspension stiffness, remember my saying: “The stiffest end of the car goes through the guardrail first!”

An alternate method of dramatically increasing the rear sway bar stiffness is by welding the integral rear sway bar solid. Set the ride height first, then weld the sway bar bracket to the sway bar.

Springs

The next stage is to increase the spring rates. Some chassis builders have different philosophies with regards to springs. Some say run soft springs with fat sway bars, others say run stiff springs, and use sway bars to balance the car. With all my sway bar work, and all my time behind the wheel, I feel like I want a more stiffly sprung car, but only slightly more so. The front of the Civic uses Torsion Bars, and the rear uses Coil Springs. Aftermarket torsion bars are getting hard to come by. Lightspeed doesn’t appear to stock them anymore, but check with them personally. Ground Control lists 23mm, 24mm, and 27mm bars for about $200 US. Money well spent, but you should phone them up to help you decide on which size is what you want. Having raced with a fellow running 27mm bars, 27mm is VERY stiff, and he recommends going a bit softer.

You could get new torsion bars fabricated by a spring shop, but I doubt that it would be cheap.

If you’re on the cheap and don’t mind using factory parts, apparently torsion bars from a Civic Wagon are stiffer. I bought some from a wreckers, so I’ll let you know when I get around to trying them. Integra torsion bars are about 2 1/2″ longer, thus requiring the Integra tubes. You’ll have to drill new holes to mount the tubes to the floor to make it fit.

Honda lists different part numbers for Civic Hatchback bars and Wagon Bars, so although they are both 20mm in diameter, they are a different product. They also have different part numbers depending on the vehicle year. Whether they are different spring rates, or are merely splined for a different ride height, I don’t know. Interestingly, the 400lb heavier Acura Integra also has 20mm torsion bars.

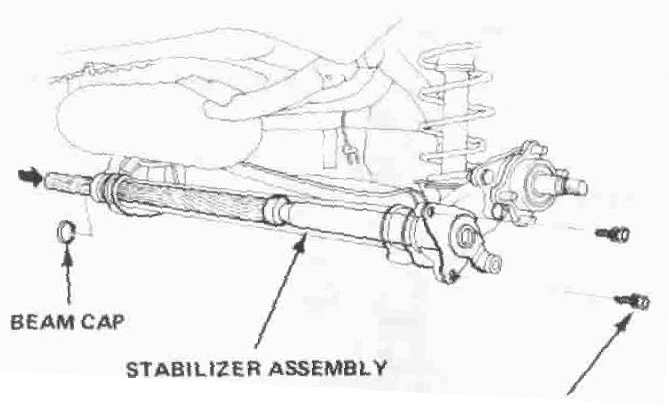

Whichever method you chose, you will need a BIG hammer to get them out. I mean BIG! Remove the front control arm rubber seal the rear tube cap, remove the rear snap ring, and wail on the bar until you can remove the small snap ring from the front. Now pound on the bar, sending it rearward until you hear it fall free into the tube. The front splines are smaller than the rear splines.

Rear coil springs again vary in stiffness. Nicely, they are all interchangeable. I don’t have specific spring rates, but based on what I know about springs, the Hatchback springs (52441-SB3-692) appear to be the softest, Integra springs (52441-SD2-A01) appear to be stiffer (and $3 cheaper than the Honda springs!), while Wagon springs (52441-SB6-003) appear to be the stiffest. All you’d have to do is cut them down to the installed factory ride height (trial and error).

Shocks

I also bought a set of four Tokico Illumina adjustable shocks. I installed them with new dust boots to replace the rusted originals. The Civic is now much more tight on the road. My original front struts were so worn, any sharp bump wouldn’t be sufficiently suppressed to prevent bottoming (not that shocks are the saving grace against bottoming – that’s the spring’s job!). I have both the front and rear shocks set at 2 (out of 5), and the ride is pretty stiff. The violence of the weight transfer in cornering is reduced, as the shocks are slowing down how quickly the weight shifts to the outside. The “feel” of the car is much better, too.

The stiffer shocks (even on such a “low” setting) transmit more force to the body. All the evil squeaks the body gave are now worse, and the doors rattle more. I did have to re-adjust the hatch, as the stress on the body from the suspension was making the rear hatch squeak and rattle. It turned out that the car had been rear-ended fairly hard before I got it, and the body shop (or whomever did the repair) didn’t do a very careful job of adjusting the hinges and latch.

Lowering

I went through a “lowrider” phase with this car. I wanted to see why people always said “never cut coils to lower your car.” I also though it would looks cool, but I’ve never done one, so why not?

I removed the front torsion bars, reinstalled them a notch lower and unwound them. to match the front, I chopped four coils off the rear springs. It looked cool, drove terrible, and either scraped, high-centered or nosed everything. I had to wedge a baseball bat between the back tire and fender, and roll the car forward and back to roll the fender edge under and out slightly so the tires wouldn’t rub. Big bumps would still rub the tires on the inside of the quarter panel. I kept it that way for about three months, and then bought new coils and put it back up.

When it was low, it sat really nicely, attracted a lot of attention, and caught stares as I caught speed bumps. It became very nerve-wracking to drive, because I was always looking out for bumps, dips, cracks, or anything that would become a kidney-jarring impact. Your eyes should be looking for pedestrians, traffic, or other threats. See Handling for more information on the “joys” of lowering.

Would I lower it again in future? Probably, but I would definitely purchase stiffer torsion bars. It really would look cool at least an inch lower (famous last words). It really needs stiffer springs to prevent bottoming, but I am not looking forward to driving over a coin and telling if it’s a dime or a nickel. Bigger springs, stiff shocks and 50 series tires are bound to get my passengers complaining….

I had a fellow email me with pictures and instructions on how to modify your struts for more suspension travel. Unfortunately Windoze decided it needed a fresh install, and I lost everything. If you have pictures depicting how to modify your struts, please send them to me!

Modifying your struts consists of grinding off (or seriously reducing) the little tab at the bottom of the strut thus allowing the strut to sit lower in the steering knuckle. A groove should be made in the side of the strut so the through-bolt can correctly secure the strut in the knuckle.

Strut Tower Bar

I was leery about the effectiveness of “Strut Tower Braces,” but since it only costs about $2 to make one, I installed one anyway. Since the car is not fuel injected, it is not easy to make it from one strut to the other. I had to bend the bar around the air filter and tie the bar into the firewall (now illegal in SS or SP). The difference was noticeable, but minimal. The front end seemed to dart around less, and felt more solid. A difference in cornering? I don’t know. I would like to get twin Weber sidedrafts then install a straight strut tower bar for maximum effect.