Start – 1 – 2 – 3 – 4 – 5 – 6 – 7 – 8 – 9 – 10 – 11 – 12 – 13

In which I mount a rad, build a transmission, and begin wiring.

I visualized a more modern oem-style radiator mount, and fabricated stand-off thingies to make that happen, using the rubber bitties stolen off cars we stripped at the school.

Only I didn’t think that all the way through, and it all ended up hanging to low in front. So I cut them off.

Instead, I came up with a simple rad mount using 1/4″ rod, some 3/4″ flat bar, some washers and some rubber stand-offs I bought for the Hideous Hardbody, but never used.

Probably too flimsy to last. Something’s going to break…

Held in by carriage bolts, because I seem to be out of regular bolts. Go figure.

Need to see what I have in the way of electric fans in my junk pile.

50% off sale at Pick-N-Pull, and I wanted deeper gears for the Firefly. In my mind, I wanted 3.73 gears, so I searched for an S10 with RPO code GT4. No luck. But I ~did~ find H04, which is 4.11 gears. Unfortunately, I broke the cross shaft bolt and did not bring a drill, so no luck.

Then I found one with RPO GU6 (3.42 gears). Tempting, but did not seem as deep as I wanted.

Then I did the math. RPM = (speed x gear-ratio) / (338 x Tire-Dia)

4.11’s with a 22.6″ tire would give me 3800rpm at 100km/h. Not really good.

3.42’s would give me 3200rpm at 100km/h. Still kinda high.

Turns out the 2.73’s in the Firebird axle would cruise at 2500 rpm, which is just fine, so I wasted my time trying to get gears at the wreckers.

Then I remembered I had a 3.42 axle at school. Just sitting there. Waiting. Patiently.

Cruising rpm be darned.

I want the acceleration to make all my four letter words have five syllables.

Going a bit artsie today. Freshening a “free” TH350 with new seals for the Firefly.

Cooling system is pretty much done. Also picked up an alternator and brackets since I am not using the serpentine system from the ’88 Firebird donor.

Yep – it all fits under the hood

Pick-N-Pull trans cooler, still to hook up

I don’t remember what the fan is out of – maybe a Lumina van we cut up at school? Some trimming and creative mounting made it work.

I’m thinking or adding the defroster back in, so the cooling system might not be done after all……

Fan mount made out of real metal (June 2015)

So easy making things attach with ends like this

Got the rebuilt TH350 in now (just fresh seals and internal modifications), and got the old one in storage until the inevitable. SO nice pulling transmissions when there is no floor. I forgot to snag the trans mount….

Way back when I got the blue transmission (now gone), the kiddies at school broke the dipstick tube off at the base. The student skill at brazing was equally proficient, so to use this tube again, I cut off the offending end, and machined a new end out of scrap. Yes, I know you can buy replacement tubes, or the newer, better “top hat” sealing tubes, but this was free. Yes, two o-rings.

This is the first post now, in about a year. I’ve been building The Workshop, and as of this writing, it is near enough to completion, that the Firefly moved in. Chances are it will get a whole lot more finished with light, heat, and a hoist.

Shop is pretty much done now, so here’s the teaser-trailer:

Ok, officially back at it.

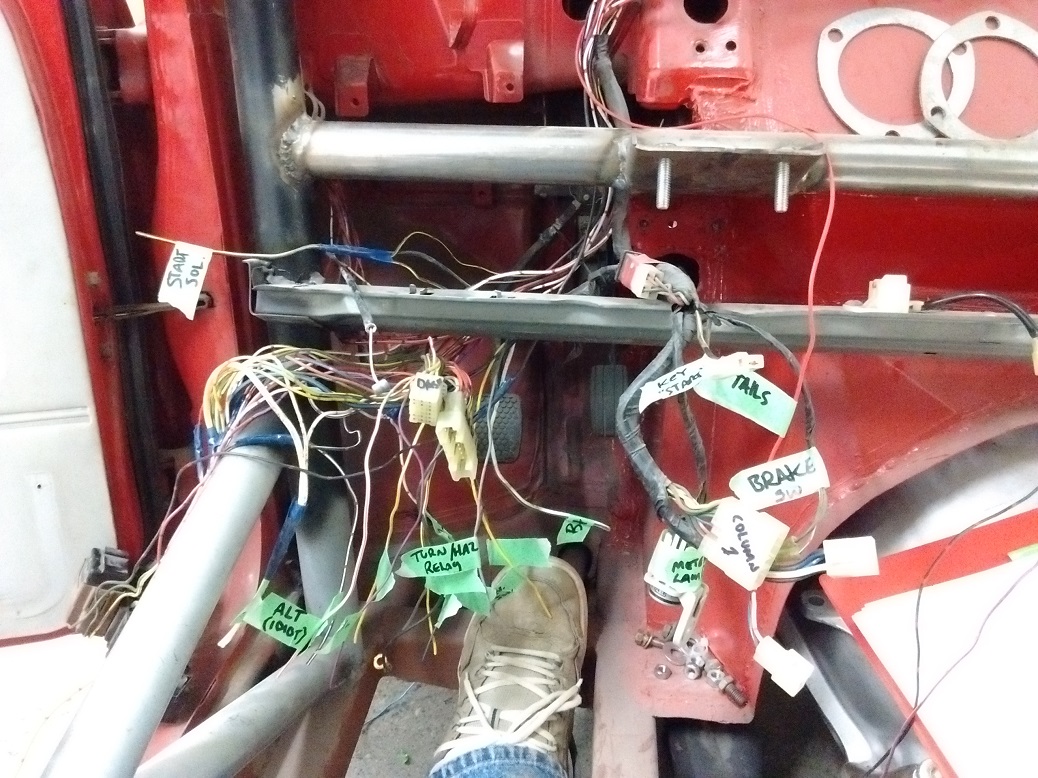

Dragged the Big Box of Wiring out of the basement, and started going through the Firebird harness to pick out all the EFI-Relevant stuff. It’s as fun as it looks.

Took me a while to find the Fuel Pump Switch. Looks like I did not plan the header tube out all that well.

I have some scrap header tubes in my collection. It might be easiest/simplest to pull the header and change that offending tube. I have room to run it forward a bit.

I took the dashboard out to make it easier to wire. This is going to be a challenge. Also, I have relented and decided to run a heater and defroster, but I this will be another challenge, because the defrost ducts and heater guts have to go where engine currently is. This will take some thought.

So, I let that simmer in the back of my head, along with the placement of the ECU, and any suspected future changes of wheel well size (dang bigger tires).

I cut a hole in the firewall for the engine harness bulkhead connection thingie from the Firebird, and started wiring up the engine. Lots of shortening and routing, and I ran out of heat-shrink. Overall, I ~think~ I am happy with my results.

ECU wiring under the hood is 95% complete. Figuring out where to mount the computer. Looking through boxes of wires to find the dash harness….

I think I have a solution for the heater core. This is NOT fun to place, but I have no options. I will be adding some kind of fan and ducting to this to blow air to the new defrost ducts. The original cowl inlet is paneled over, since engine fumes would otherwise get into the passenger compartment

The past year and a half of building the shop had me venturing back into the “obsessive” end of things – I feel myself slipping back down to a more productive “git’er dun” mode. This isn’t as thoroughly well thought out as I’d like, but I’m mostly sure the end result will work.

Went to look at a ’65 C10 step side that popped up locally. I want one to replace The Crusty Chevy. Turns out when he said “yes it has BC registration,” what he meant was “no I don’t have BC registration.” Which means a vehicle inspection, which means I have to build it once to pass, then disassemble it to molest it properly. I didn’t even open a door or pop the hood, just “thanks for your time” and walked away.

There are more fish in the sea.

I worked on the dashboard wiring harness today. Picked out wires and options I don’t have, along with things I won’t have. I kept V+ and GND for the heater so I can power a defrost of some sort. I’ll have to run it through a switch. I will probably replace the entire heater controls with a basic switch panel, since there isn’t enough room behind the dash to fit true heater controls (much less a heater).

I ~may~ be lucky, in that the speedometer “appears” to have a Vehicle Speed Sensor built in. This isn’t used on this standard transmission Turbo model, but this might be all I need to make the TBI ECU happy powering a TH350.

Not a whole lot of change in this harness:

Previously, I’ve been putting together some new defrost ducting with 1″ PVC tube left over from doing sprinklers. I’ve cobbled together some adapters to connect it to 1-1/4″ hose of some sort.

Picked up a cheap 4.7″ computer case fan, which ~might~ be enough to defrost the windshield. I drew up a fan-to-twin-outlet in AutoDesk Inventor, and printed it out in my Drafting lab work. I may use it as-is, or I may waste-cast it in the Metalshop. Perks of being a shop teacher, no doubt.

At Home Depot this evening, I found some 1-1/4″ hose for a sump pump, which is certainly both flexible and cheap enough to probably do what I need it to do for the defrost.

Here is what I’ve come up with for the defroster. Not sure it will work, but I will feed these with two 1-1/2″ flexible hoses.

Holes drilled in the top of the tube to line up with the existing vent holes in the dash.

And put a big dent into sorting out what wires went where, what I needed, and what the TBI ECM needed. I ~think~ I’ve got this all ready for connecting together. Interesting studying the Firefly wiring diagram figuring out how it all works, and what I don’t need. A bit of fun, since I didn’t strip the car 7 years ago, it was kids – and I could only trust that it was all there. So far – it is. Good job, nameless student of yore.