INTRODUCTIONBefore we get into this, I want to be very clear on some expectations: RESPECT

ATTEND

TRY

PRODUCE

FOLLOW INSTRUCTION

MAKE YOURSELF EMPLOYABLE

I’m hoping this isn’t new to you (but I’ll know pretty quick if it is). |

||||||||||||||||

SAFETY |

||||||||||||||||

| Safety is the most important part of working in ANY shop. I am very very fussy about following all of the safety rules – I don’t want any one of you to get hurt.

None of these rules are silly. None of them are pointless. They are there to protect you, based on the injuries that happened before you. I want each and every one of you to be safe. We have a few assignments that we will cover: ARTICLE – Coquitlam Hoist Accident

Take care of your skin – most of these chemicals are nasty!

|

||||||||||||||||

WORKSHEET – – – – POWERPOINT(Updated Feb 2023) |

||||||||||||||||

ASSIGNMENT – Safety Booklet: |

||||||||||||||||

The Purpose….In this activity you will be producing a word processed handout on the safety of a machine. This should be review, however it’s been a long summer, and most of our brains have turned into mush, so we may need a refresher. The Procedure…You will work in groups set up by your Instructor. Each group will be randomly given a topic for which they must present an exactly 2 (two) page handout. The handout will describe each safe operation of the machine such that anyone in the class will be able to understand. Use Google to find your information. The handout must contain the following:

To make it easier, follow these easy steps (You will find this course MUCH easier if you will take the time to read the instructions!): Research the topic – gather as much information as you can Select the Need to Know basic safety Outline the steps needed to operate the machine safely, or to perform the task Organize the information into a presentable format (POINT FORM is best) Show your Instructor your progress and ask for suggestions Word process the handout, check for misteaks and hand in! ConclusionYou are done when you have completed and handed in a high quality, professional handout on your machine/process/future-technology. ReflectionWhat did you learn about communication? How did you enjoy working with your partner? What difficulties did you encounter? What was the most effective method to convey your information? There will be a SAFETY QUIZ following these units, on which you much achieve at least 80% to pass. Students will make full-sentence corrections for any question they got wrong. Students achieving less than 80% will need to write their corrections in a full sentence and re-write the quiz until they do achieve at least 80%. It is in your best interest to study the materials before hand.

|

||||||||||||||||

POWER TOOLS |

||||||||||||||||

| Power tools are a whole new level of fun and potential injury.

|

||||||||||||||||

|

||||||||||||||||

FASTENERS |

||||||||||||||||

| There are many different fasteners used in vehicles today. Becoming familiar with them, and choosing the right tool to undo them is important.

Fasteners are VERY SPECIFIC. There is magic here; use the CORRECT FASTENER always! Fastener Identification:Type of fastener Diameter Threads (ie: Bolts) Length Strength <– Critical! Coating Not just any fastener will do – it must be the right one! Fastener Tips:Always use washer to protect the part Always use NEW gaskets to ensure sealing Always tighten the correct amount (use a TORQUE WRENCH) Open in MS Word and completeLevel 1 AssignmentLevel 2 AssignmentLevel 3 AssignmentLevel 4 Assignment

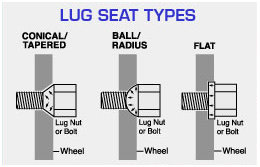

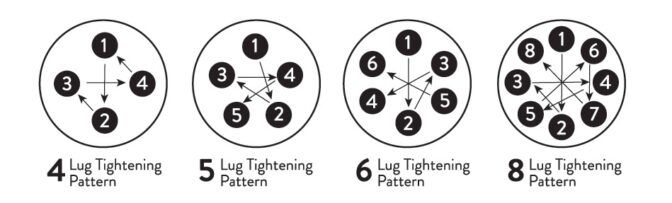

Let’s Talk Wheel Nuts!Wheel nuts are one of the (many) critical fasteners on a vehicle, and one of the MANY that students are NEGLIGENT in properly tightening. There are some basic things that you MUST do:

Anything else is WRONG;I don’t care how you “feel” about it.

^^^ Though, technically, I think the axle-shaft or hub actually failed, probably from the dastardly wrong offset wheels

|

||||||||||||||||

Hand Tools |

||||||||||||||||

| There are many, many hand tools used in mechanics that you will need to become familiar with. Using the right tool for the job will allow you to work faster and safer with less chance of damaging yourself, the car, or the tools.

If you are not sure about anything you are doing – you need to ask my help. I love teaching, and I love showing people how to do a task the most efficient way possible – take advantage of that.We have a few assignments that we will cover:

|

||||||||||||||||

WORKSHEET – – – – POWERPOINTUpdated summer 2023 & link fixed Sept 28 |

||||||||||||||||

ASSIGNMENT – TOOL BOX: |

||||||||||||||||

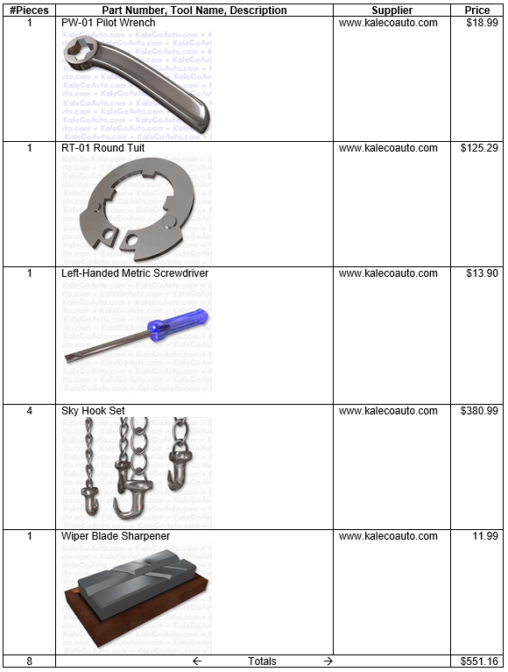

| In this activity you have $1000 fictitious dollars to spend on tools for your basic tool kit.

You must determine what tools your kit will consist of, and how much you wish to spend on each tool. Level 1: Hand tools only (do not include consumables, like oil or rags) Level 2: Power tools only (do not include consumables, or drill bits or impact sockets) Level 3: Diagnostic tools only Level 4: Autobody Tools

WHAT I’M LOOKING FOR:You may not be OVER $1000 You may not be less than $995 You may use Canadian or American dollars only. DO NOT include taxes or shipping. You must source a REAL store, with NEW tools, not Castanet or Marketplace or eBay or the like. You will create a TABLE using Microsoft WORD or Google DOCS, set up with FOUR columns, like this:

In WORD, You can TOTAL the #Pieces and Price columns easy: Click in an empty cell at the bottom of the column. Go to [TABLE TOOLS] -> [LAYOUT] -> “=SUM(ABOVE)” Watch the person beside you use their calculator, and start laughing loudly at them. Point out that this is in both BOLD, and COLOUR

|

||||||||||||||||

PRECISION MEASUREMENT |

||||||||||||||||

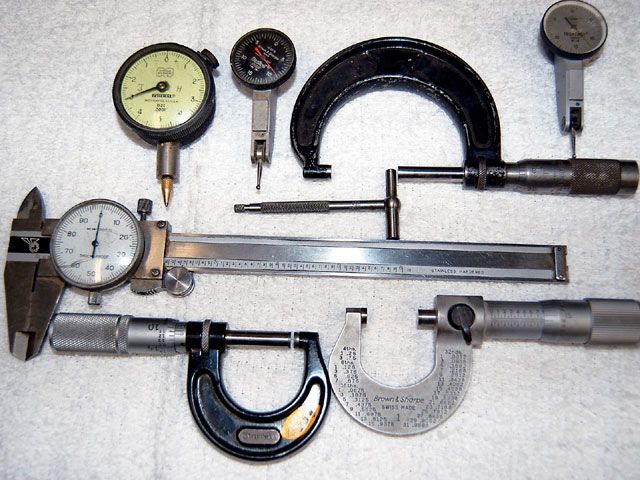

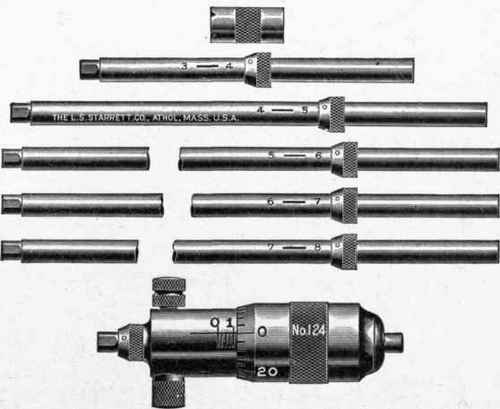

| Nothing lasts forever. Virtually all the parts in a vehicle are very precisely made. In order to perform the best, these parts must stay within an acceptable range of wear.

The difference between “good” and “worn out” can be as little as the thickness of your hair! You cannot measure this wear with a ruler, you must use more precise tools such as a Micrometer and a Vernier Caliper. THEORY – Precision Measurement

ASSIGNMENTS

|

||||||||||||||||

BASIC SKILLS |

||||||||||||||||

| I made a lot of mistakes when I was starting out as a mechanic. Being inexperienced and careless, I broke a lot of things that didn’t need to be broken. Broken parts slow you down, and makes the job become more expensive and more time consuming than it needs to be.

Getting your head wrapped around “The Way Things Are Done” can really help you out. “Learn from the experience of others – you don’t have enough time to make them all yourself.” You will be working on other people’s property, and as such there are some things you need to keep in mind.

|

||||||||||||||||

POWERPOINT: The Golden Rules |

||||||||||||||||